Publishing your designs onto garments is a method which has been around for many years even so, the method has never been as effective because it is these days. With breakthroughs in modern technology, DTF (Direct to Video) transfers took over the custom apparel market place. Dtf transfers are definitely the new era of customized stamping. With this post, we will take a closer inspection at what Dtf transfers are, how they function, and why these are the way forward for personalized publishing.

1. What are Dtf transfers?

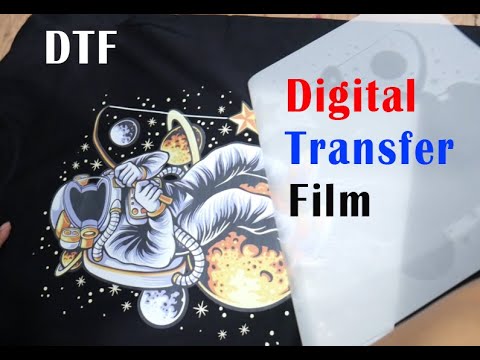

Direct to Film (DTF) transfers certainly are a present day version of the traditional heat exchange means for generating a layout onto clothes. Instead of making use of vinyl or other transfer methods, Dtf transfers use a covering of movie that embodies the print on the apparel, which is then printed out on. The video evaporates from the printing device, printing the designed artwork to the material.

2. How can Dtf transfers job?

The DTF transfer approach starts with generating the design you need onto a transfer video using a specific computer printer. The printer deposit dyes or pigments onto the shift motion picture, and after that an sticky covering is included. As soon as this exchange video provides the design, this will make it applied to real-time goods employing heat shift click equipment. The high temperature and pressure from the press equipment trigger the sticky about the move motion picture, which attaches the design and style for the clothes.

3. Great things about Dtf transfers over classic printing strategies

There are several benefits of Dtf transfers over classic generating techniques. To begin with, Dtf transfers create clear and-quality designs with a advanced level of detail that continues beyond traditional heat transfers due to the fade away-resistant ink cartridge. Additionally, there is a higher connection power than classic temperature exchange approaches, letting the look to adhere to the materials smoothly without removing or cracking. Lastly, the DTF move strategy is far more inexpensive than standard screen printing methods, as it needs less set up and lower bare minimum buy levels.

4. Constraints of Dtf transfers over classic publishing techniques

In spite of the benefits of custom apparel, there are many restrictions that include using this approach. It is essential to note that DTF shift movies really need to be printed on sizeable ink jet printers with specialized ink cartridge that may be quite expensive. The gear also demands routine maintenance to preserve the print quality, and the printing speed and available colours are relatively limited compared to regular screen printing.

5. The future of Dtf transfers

Dtf transfers came on powerful from the printing world recently because of the crystal clear and vivid print good quality and simplicity. Paper top quality talks for itself and suggests that the technique is here now in which to stay to the near future. Hunting ahead of time, it’s reasonable to say that DTF move printing may become much more readily available, and the caliber of printing will advance as technology increases, supplying better and a lot more in depth printing.

In a nutshell:

Dtf transfers offer you numerous advantages over standard printing approaches, which include the ability to develop high-high quality, extended-long lasting, and fade-proof clothing styles. While there are many limits for this method, the benefits over-shadow the negatives. As printing technology continues to develop and turn into more inexpensive, we are able to anticipate seeing Dtf transfers become the new common for personalized clothing publishing.